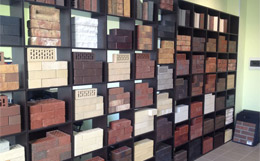

Types of brick - classification of brick products

Brick as the oldest building material is found almost everywhere, it is universal, beautiful, durable. Let's try to understand in detail what types of bricks are, depending on the material of its manufacture, the scope of its application, manufacturing methods and sizes. The format and composition of it is diverse, this material has passed a difficult path in the history of civilization.

Content:

Types of bricks depending on the material of manufacture

Each type is designed for its own spectrum of application or process. And the first indicator by which brick can be classified is the material from which it is made.

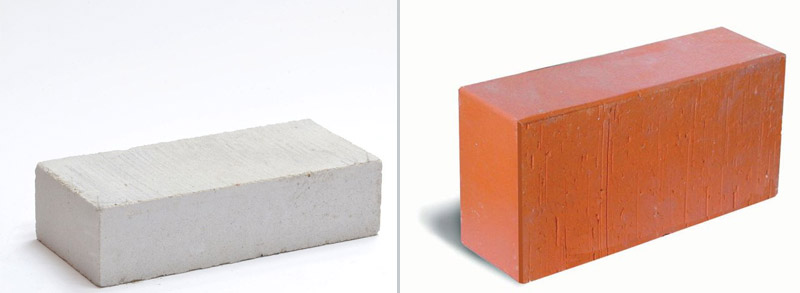

Ceramic

Ceramic bricks are made of high-quality clay without admixtures of marl and sulfates. Usually, raw materials with a minimum percentage of undecomposed calcite in the composition are used. In the beginning, the brick is molded, after which it dries and is fired in a furnace at a temperature of 1000 0C. When subjecting a brick to heat treatment, it is very important not to allow burnout or underburning. And in the first and second case, the quality of the brick will significantly deteriorate. The unburned brick looks light, and the burnt brick will have shades of black. A good clay product has a semi-matte surface, it produces a distinctive sonorous sound upon impact, and has a porous structure at a break.

Silicate

Silicate brick consists of refined quartz rocks (sand), and lime and moisture themselves account for about 10% of the mass of raw materials. The percentage may vary on the composition and quality of the prepared mass. The main condition in the production of a good product is the cleaning of components from organic impurities, clay, manganese. Lime should not contain a lot of calcium oxide, should not be burnt. The manufacturing process takes place under great pressure. This type of brick is warmer than ceramic. It is used for the construction of walls and partitions.

Hyperpressed

The composition of this type of brick usually includes various screenings of calcareous rocks, marble, shell rock and dolomite, formed during open pit mining. These components make up to 90% of the volume of the mass of raw materials. The second indispensable component of the composition is high-quality Portland cement. It plays the role of the main astringent component, occupying 6–8% by volume of the prepared mass. Brick is made by pressing in special forms. Of great importance for pressing is the quality of the water itself, which is part of the composition as an agent of a chemical reaction. As a result of pressing, bricks of an ideal shape and size are obtained. Hyper-pressed bricks are used for wall cladding of buildings. The surface of the brick itself can be smooth or have a texture under the so-called "fragmentary stone".

Brick classification according to the purpose of use

In construction, several types of bricks are distinguished, depending on the area of application.

Construction or private

Building or ordinary brick (GOST 530–2007 of 03/01/2008), used in the arrangement of both the internal walls of buildings and the exterior. It is possible to use such varieties of bricks for building a house, but only with the subsequent warming or protective decoration of the facade. This type of brick is far from ideal and may contain small chips, which, however, do not affect its strength.

Facing brick

Facing brick, (other names: front, facade) - this is the most even and ideal material without defects.Maximum permissible deviations according to GOST are not more than 4 mm. in length, 3 mm. in width and 2 mm. in height. As a facing, ceramic, silicate or hyper-pressed brick can be used.

The relatively low cost of facing ceramic bricks has advantages over decorative types at a price. Using this brick as a facing brick, you should be aware that it is used in lowlands and damp climatic zones, due to its low hygroscopicity. Where the use of silicate species is unacceptable due to the hydrophobic properties of the product (moisture absorption). On the contrary, in dry and hot latitudes, silicate will be the best choice of all types of facing bricks, the building turns out to be stable to temperature fluctuations, cool.

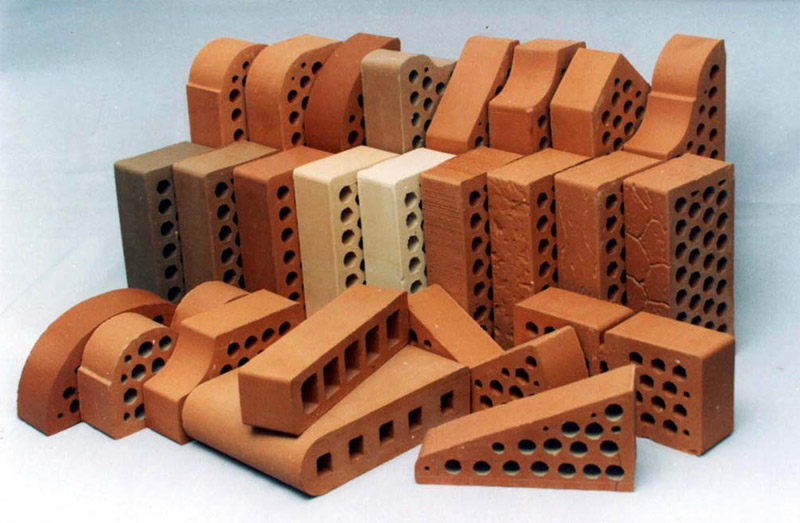

Among the facing bricks, two varieties are distinguished - these are textured and shaped bricks.

1. Textured brick, with smooth or uneven edges (Torn stone) produced for cladding building facades and equipping fences. The edges of such a product can be either rolled, smooth, or without treatment.

2. Shaped option with different profile configurations, designed for laying complex shapes around windows, window sills, arches, pillars, fences, arbors. For example, shaped types of building bricks with round edges for corners are perfect for arranging complex building facades, namely corners.

The gamut of colors of facing types of bricks is large and ranges from a light yellow hue to almost black.

Stove, fireclay brick

Oven, chamotte brick, this is a refractory product according to GOST 390–96, has the correct geometric shape, a granular base and can be straw-colored, with reddish or brown spots. They serve for insulation and construction of facilities subject to constant high temperatures (stoves, fireplaces). Forming a heat-resistant shell, with the function of protecting the furnace from direct fire or hot coal.

The main qualities that such products should possess: heat resistance, high cyclicity, low thermal conductivity. Fireclay must withstand quite a long heating and many cycles to a temperature of 1000 ° C without loss of quality and its strength. The refractory version is not necessarily produced in the correct form; there are other formats for such products (SHA-25 and SHA-47) - wedge-shaped.

Brick brick

Ceramic clinker brick is made of refractory clay layers that sinter to form a homogeneous mass. In the selection of clay mass as a raw material for production are treated carefully. The composition of the clay should be clean and plastic, it should not contain chalk and alkali metal salts, unnecessary minerals. In the heat treatment process, the clinker acquires the highest strength and good density. Low hygroscopicity and unpretentiousness to freezing temperatures. Shale clay has a suitable composition for this, it is flexible and refractory.

This brick has many colors and textures. Therefore, clinker brick is used for wall cladding, socles, paving garden paths.

The difference between ceramic bricks by the method of manufacture and type of molding

The production of ceramic bricks is divided into two main types according to the molding method. Brick of plastic molding type and brick of semi-dry molding type.

1. Plastic Molding Bricks. Plastic molding involves several processes and is performed from plastic clay masses with a moisture content of 15-21%. The main types of building bricks are produced by extruding through profile mouthpieces of various screw presses. There are both vacuum plants and conventional ones. Solid stone is usually pressed on equipment without a vacuum, and hollow options - on vacuum plants and presses.

2. Semi-Dry Bricks. Semi-dry molded products are also produced from clay using pressing and firing. But the main difference from the plastic method is that the raw material is first brought to a certain moisture content (about 8-14%). Then it is pressed into molds, and only then it is fired in rotary or tunnel kilns.The low humidity of the workpieces allows the finished products to maintain the correct shape and a clear surface.

High-quality types of bricks for building a house, mainly obtained by plastic molding. They have smooth edges and smooth surfaces.

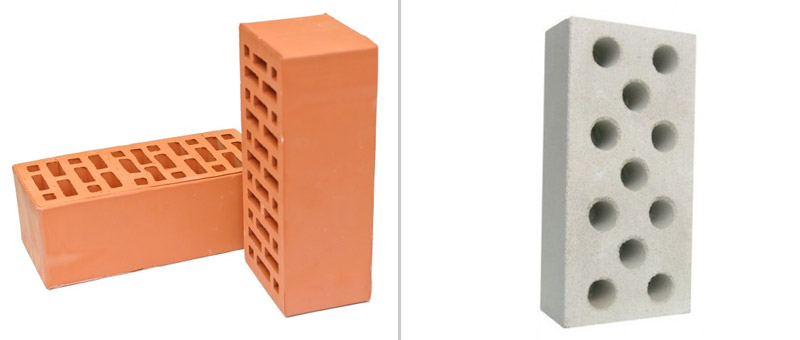

Types of bricks, depending on the nature of the filling

Depending on the filling, the brick can be hollow and solid. The choice of this or that brick will depend on the sphere and object for the construction of which it is supposed to be used.

Solid brick

As the name implies, such a brick has no voids. In a standard silicate product, the hollow in the form of pores does not exceed 12–13%, for a full-bodied version. In a clinker product, the porosity of the material is up to 5%. Bearing walls are erected only with solid brick.

Hollow brick

For hollow silicate bricks, the hollow rate varies from 24-30%. The performance of ceramic products is slightly different. Hollowness can reach 45%. Holes or chambers perfectly retain heat, increasing the percentage of overall soundproofing of the walls. There is a decorative and facing brick with 4, 6, 8, and even ten chambers, both round and rectangular. Naturally, the filling of bricks affects the strength of the entire structure being constructed. Hollow options are used mainly for the construction of partitions. Types of brick with voids are not used in the design of fireplaces and stoves.

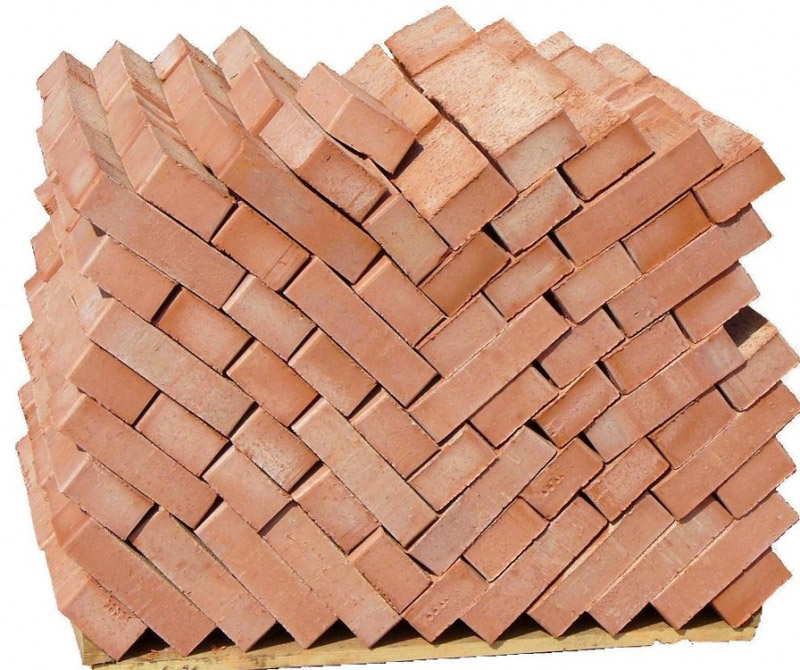

Types of bricks and their sizes

When starting to search for suitable material for cladding or walling, it is worth paying special attention to standards on the edges of the product. This will help to correctly calculate the masonry step and choose the amount you need.

There are the following 3 standard brick sizes:

| Title | Size mm |

|---|---|

| Single | 250x120x65 mm. |

| One and a half | 250x120x88 mm. |

| Double | 250x120x138 mm. |

European standards have the following sizes:

DF-240x115x52 mm;

2 DF-240x115x113 mm;

NF-240x115x71 mm;

RF-240x115x61 mm;

WDF-210x100x65 mm;

WF-210x100x50.

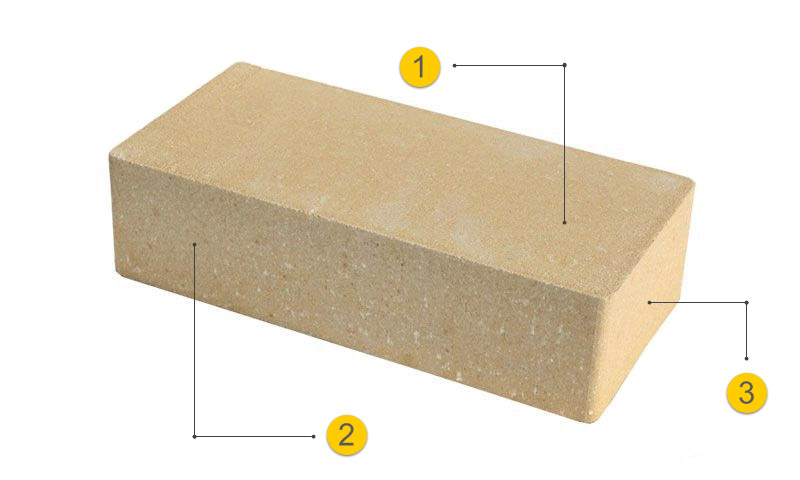

Regardless of the size, each brick has the following 3 sides:

1. A bed is the working part of the product on which it is placed.

2. The spoonful of stone is the edge of the product.

3. The bump is the smallest facet of the product.

At the end of the topic, I would like to add some tips on choosing brick products.

The first thing to do when choosing a brick is to find out its brand, strength, resistance to external influences. Explore already built structures or buildings from it. Find out what time the building is in operation, whether there are delamination, cracks in the walls, corners.

The second, and probably the most important rule, inspect the production or warehouse before buying for the subject of battle, defective size, balances, unsold lots. The appearance of the product and the neatness of production can tell a lot about quality.