What kind of brick is needed for laying the furnace - the right choice of material

For the construction of heating stoves in individual residential buildings, ceramic bricks are widely used. The construction industry produces a wide range of bricks for masonry kiln, but which one to choose from the proposed range? Before we consider this issue, you need to understand the fact that two types of bricks are used for laying the furnace - this is a simple ceramic brick, but with certain characteristics, which is used for laying the external elements of the furnace, chimneys and refractory or fireclay brick, which is used for masonry furnace furnaces.

Content:

- What properties should have a brick used for laying a furnace

- The use of different types of bricks for laying various elements of the furnace

- What characteristics should have ceramic brick for laying the furnace and fireclay brick for laying the furnace

- Choosing a kiln brick manufacturer

- Methods for determining the quality of stove bricks

What properties should have a brick used for laying a furnace

The kiln brick must meet the following technical requirements:

- Resistance to high temperatures and effects of an open flame.

- The ability to accumulate heat and keep it for a long time.

- Sufficient mechanical strength.

- Resistance to significant temperature fluctuations.

Solid fuel furnaces are built of ceramic bricks that meet the requirements of GOST 390-96. This standard came into force on July 1, 1997 and establishes the technical conditions that these products must comply with in shape and size. The regulatory document also defines the requirements for the use of products depending on the maximum ambient temperature.

For ceramic bricks intended for the construction of thermal units, more stringent requirements apply than to other building materials. In the furnace of a furnace, the flame temperature can exceed 1000 ° C; accordingly, its walls are subjected to significant thermal loads. Thermophysical parameters of the material used must be higher than the specified value.

During operation of the furnaces, they are regularly cooled in individual cases and to negative temperatures. In this case, the brick undergoes a significant difference in ambient temperature, which leads to thermal expansion with subsequent compression. The product must have a sufficient margin of safety to successfully resist this phenomenon and to avoid deformation and destruction.

The brick used for laying stoves must have a sufficiently high thermal conductivity and the ability to accumulate heat. The first property is necessary for the rapid heating of the room and the transfer of energy from the burnt fuel to the external environment. The second quality allows you to maintain this process after the cessation of combustion in the furnace for a long time. This allows you to maintain a comfortable thermal regime for a long time.

The use of different types of bricks for laying various elements of the furnace

Solid fuel furnaces have a rather complicated design, the components of which work under certain conditions. The question arises, what kind of brick is needed for laying the furnace and its elements?

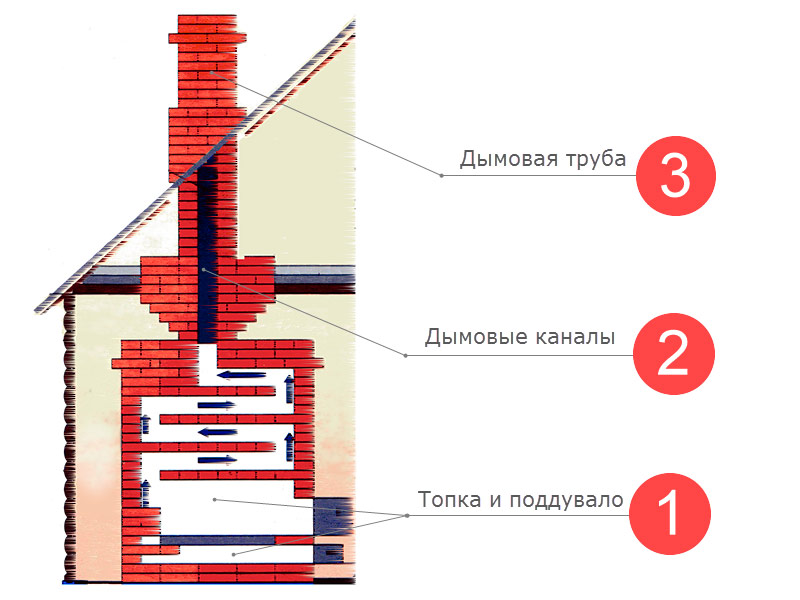

The device of the heating furnace is as follows:

1. Firebox and blew.

The combustion chamber mainly has two-layer walls, the inner one is made of refractory (fireclay) bricks, the outer one is made of facing ceramic bricks. The firebox is erected from fireclay bricks with maximum refractory properties. The external finish of the furnace works under less stressful conditions and it is possible to use facing bricks with excellent decorative characteristics.

2. Smoke channels.

Smoke channels are a large heat exchanger and the temperature in them, although lower than in the furnace, is still quite high. For laying these elements of the furnace, fireclay bricks are used. Outside, the structure can be faced with ceramic tiles or facing bricks.

3. Chimney.

The chimney is in direct contact with the atmosphere and experiences large temperature differences. Therefore, ceramic brick with the highest possible frost resistance is used for it. Typically, this element also has a two-layer structure with a decorative exterior finish of ceramic brick or metal box.

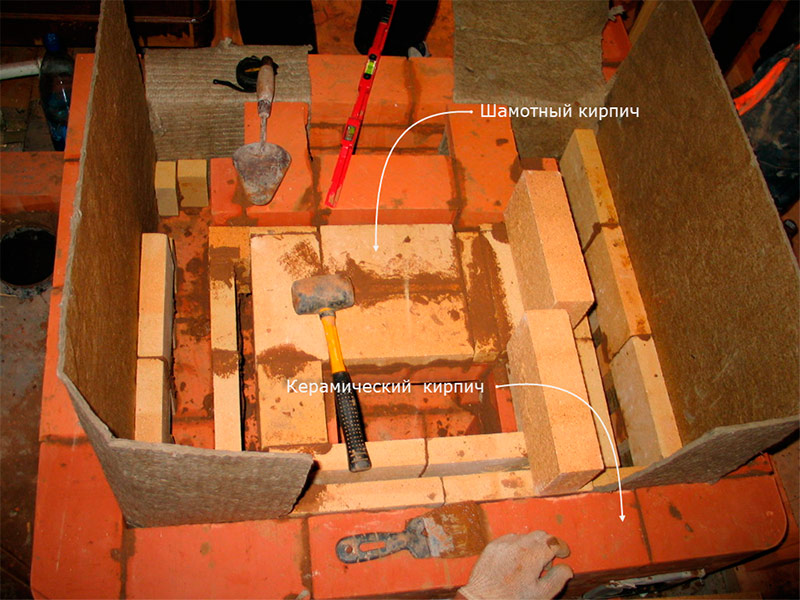

The process of laying the furnace and an example of the use of fireclay bricks for building highly loaded elements and external cladding with ceramic bricks.

The use of bricks with the appropriate characteristics for the device of individual elements of the furnace will provide maximum durability and excellent thermal properties. Experienced stove makers in the selection of material pay special attention to this issue. At the same time, a thorough inspection and rejection of bricks with large cracks and deep damage and chips is carried out.

What characteristics should have ceramic brick for laying the furnace and fireclay brick for laying the furnace

Characteristics of ceramic bricks for laying external elements of the furnace, smoke channels and pipes

As we said earlier, a certain type of ceramic brick is used for laying the furnace, now we will consider what basic characteristics this brick should have.

Brand by density. The first thing you need to look at when choosing a ceramic brick for a furnace is the density brand. The brand of ceramic brick in density is set in accordance with the requirements of GOST 530-2012. For its designation, an alphanumeric coding is used, consisting of the letter "M" and a number from 25 to 1000. Please note that this indicator does not indicate the quality of the brick, but only shows its density when pressed. This indicator is important because the denser the brick, the slower it heats up, and therefore cools more slowly. The fact that the brick will cool slowly is certainly good, because the stove will give off heat for a longer time. But it’s more difficult to heat a stove built of too dense bricks, especially when it has completely cooled down. Balance is important here, therefore, brick is used for masonry with a density not lower than M-150 and not higher than M-250.

Frost resistance. Frost resistance of a product is defined as the ability to withstand a certain number of heating and cooling cycles. This indicator is indicated by the Latin letter F with the addition of a number from 25 to 300. The frost resistance of ceramic bricks is important in the construction of external elements of a heating furnace, such as chimneys. The thing is that this integral part of the furnace is in very severe conditions of constant temperature difference. This has a huge effect on the brick used for laying the pipe. For the construction of such structures, it is best to use ceramic bricks with frost resistance from F75 to F100.

Thermal conductivity. The thermal conductivity of ceramic bricks will depend on its density and for products used for masonry, it should be in the range from 0.59 to 0.72 W / (m × ° C).

Fullness. For laying the furnace, only full-bodied ceramic bricks are used.

For laying the combustion chamber of the furnaces, fireclay brick is used with the following characteristics

- Product brand: SHAK, PB, ShA, ShB, PV, ShV and ShUS.

- Softening point not lower than 1300 ° C.

- Uniformity of blocks throughout the volume.

- High density and low porosity of products.

The operational characteristics of the furnace and the duration of its intended use directly depends on the quality of the refractory bricks of which the furnace is built.

The building materials market offers an extensive range of products suitable for masonry fireboxes. The question arises from which brick it is better to lay the stove so that it is durable and retains its properties for a long time. Experts recommend the use of fireclay chamotte semi-acid brick. These products have the best ratio of characteristics in terms of cost and thermophysical properties and quality.

The main technical characteristics of ceramic bricks used for the construction of solid fuel furnaces are summarized in the table:

| Indicators | Normal grades | ||||||

|---|---|---|---|---|---|---|---|

| SHAK | SHA | SB | BW | SHUS | PB | PV | |

| Fire resistance, ° C | 1730 | 1600 | 1650 | 1630 | 1580 | 1657 | 1580 |

| Porosity,% not higher | 23 | 24 | 24 | 24 | 30 | 24 | 25 |

| Product tensile strength, N / mm2 | 23 | 20 | - | 20 | 12 | 20 | 13 |

| Softening start temperature, ° C | 1320 | 1300 | |||||

Choosing a kiln brick manufacturer

The market for this type of building materials is extremely saturated with products of domestic and foreign companies. Products manufactured by enterprises from Russia, Belarus and the Baltic republics are widely represented in this segment.

Vitebsk brick factory workshop number 1.

Ceramic bricks of this manufacturer meet the requirements for material for furnaces according to the density brand. Frost resistance of products is extremely low. The density grade is 180 - 200. Brick can be used for facing the stove and chimney channels, it is unsuitable for other elements. We can say that this is one of the most common, to date, materials for the construction of the furnace. It can not be used for laying the furnace and the first chimney of the furnace. It is required to make the lining of the furnace and the first chimney with refractory fireclay bricks.

With constant direct contact with fire, this brick is quickly destroyed. Since the products have low frost resistance, the use of this brick for laying the outer walls of the chimney street pipe is also excluded. The advantages of this material include the fact that this is one of the most budget options and given all the nuances to use it for laying the furnace is quite possible. Has 2 working surfaces. In general, the quality of this brick can be described as satisfactory.

LODE.

Brick brand LODE is made in the Baltic states. Ceramic brick has a high mark in density - 500 and frost resistance. The product is used for facing the outer surfaces of the furnace and chimney. Brick of this brand has various forms and is often used to create all kinds of decorative elements of the furnace. In its main purpose it is a facing brick.

Borovichi brick factory.

Products Borovichi brick factory located in the Novgorod region. Mass production began in 2011, experts evaluate its quality as good. The density grade of ceramic brick M-250, frost resistance at F25. Significant deviations of products from the sizes established by standards, up to 10 - 12 mm in one batch, are noted. This must be taken into account when laying the furnace and it is best to take a little more brick than necessary. Further, it all depends on the professionalism of the stove-maker and his ability to select the necessary products. The brick has rounded upper and lower edges and 3 work surfaces.

Refractory or fireclay bricks of Russian production.

The quality of the products varies greatly, from frank marriage to very decent products. Fireclay brick has an even cream color and high density, the shape is regular with right angles. As we found out earlier, this brick is necessary for lining the combustion chamber of classical stoves, hearths and fireplaces. But it’s rather difficult to single out certain manufacturers here.

The answer to the question which brick is best for the furnace is usually decided by the customer in agreement with the master. It takes into account several factors, among which the main ones are compliance with the requirements of standards and cost.The operational properties of the structure depend on the correct choice of refractory bricks; saving to the detriment of quality is expensive.

Methods for determining the quality of stove bricks

Verification of compliance of this type of building materials with the requirements of regulatory documents is carried out according to the methods approved by the Gost series. Each of them is designed to determine the individual characteristics of refractory bricks:

- GOST 5402.1-2000. Method for determining residual deformations after heating.

- GOST 4069-69. The method of monitoring the fire resistance of products.

- GOST 151136-78. Methods for measuring damage to corners and edges of ceramic blocks.

Brick research is carried out in laboratories using special equipment. At home, it is impossible to check the quality of refractory bricks using the methods described in the standards. The buyer has to rely on the certificates and qualifications of the master, whom it is desirable to involve in deciding on the choice of material for the construction of the furnace.

Experienced stove makers are able in many cases to determine the quality of refractory bricks according to some criteria. Furnaces are built only from solid ceramic bricks with a brand from M150 to M250. In this case, the certificate must contain a note stating that the specified product is intended for this type of work.

The following methods are used to determine the properties of bricks:

Vibration and sound. On a large facet of the brick, which is kept on weight, a weak blow is applied with a hammer. The tool should bounce off the surface with a jingle. This indicates the absence of internal cracks.

Inspection of appearance. The brick must have the correct shape with a maximum deviation from the standard size within 2 mm in one or the other direction.

Internal structure. It is estimated by the state of cleavage, while the color of the cross section should be uniform throughout the area. The presence of spots indicates the presence of stress areas in the brick mass, which can cause its destruction during heating. Chamotte should not spall out from the internal structure of the material.

Using the above methods for assessing the quality of refractory ceramic bricks for construction in a furnace will allow you to choose the necessary material for this. The use of building bricks that meet the requirements of GOST will provide the heat engineering unit with an appropriate level of strength and reliability.