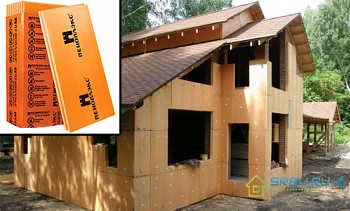

Expanded polystyrene - characteristics and selection criteria

Heating an apartment in the winter costs us oh, how expensive, and energy prices are prohibitively increasing every year. And it is very unfortunate when the heat so costly is useless to leave the apartment. Moreover, these losses are simply huge. However, there is a good way to reduce them: sheathing the exterior walls of the house with polystyrene plates. This acquaintance to all polystyrene specifications in terms of thermal insulation has a very remarkable. But are its other properties so good? Today we will talk about it.

About the properties of expanded polystyrene - in detail and available

First, we consider the technical characteristics of expanded polystyrene, which really correspond to this insulation, later we will touch on those moments of its properties that are controversial, but are constantly promoted by sellers and manufacturers.

About thermal conductivity

Expanded polystyrene is nothing more than a multitude of air bubbles enclosed in thin shells of polystyrene. The ratio is as follows: two percent polystyrene, the remaining ninety-eight - air. The result is a kind of solid foam, hence the name - expanded polystyrene. The air is hermetically sealed inside the bubbles, so that the material retains heat perfectly. After all, it is known that the air gap, which is without movement, is an excellent heat insulator.

Compared with mineral wool, the coefficient of thermal conductivity of this material is lower. It can range from 0.028 to 0.034 watts per meter per Kelvin. The denser the polystyrene foam, the greater the value of its thermal conductivity coefficient. So, for extruded polystyrene foam having a density of 45 kilograms per cubic meter, this parameter is 0.03 watts per meter per Kelvin. At the same time, it is understood that the ambient temperature is not higher than + 75% 0C and not lower than -50 0FROM.

About vapor permeability and moisture absorption

Extruded polystyrene foam has zero vapor permeability. And the characteristics of expanded polystyrene foam, which is made in a special way, are different. Its vapor permeability varies from 0.019 to 0.015 kilograms per meter-hour-Pascal. This seems strange, since, in theory, such a material with a foamy structure of steam is not able to pass. The answer is simple - the molding of expanded polystyrene foam is done by cutting a large block into plates of the required thickness. So steam penetrates through the cut foam balls, climbing inside the air cells. Extruded polystyrene foam, as a rule, is not cut, the plates exit the extruder already with a given thickness and smooth surface. Therefore, this material is not available for steam penetration.

As for moisture absorption, if you immerse a sheet of expanded polystyrene foam in water, it absorbs it up to 4 percent. Dense extruded polystyrene foam remains virtually dry. It will absorb ten times less water - only 0.4 percent.

Video. Styrofoam breathes

About Strength

Here the palm belongs to extruded polystyrene foam, in which the bond between the molecules is very strong.In terms of static bending strength (from 0.4 to 1 kilogram per square centimeter), it significantly exceeds the ordinary expanded polystyrene foam (its strength lies in the range from 0.02 to 0.2 kilogram per square centimeter). Therefore, in recent years, expanded polystyrene has been produced less and less, since it is less in demand. The extrusion method allows you to get a more modern material for insulation, durable and moisture resistant.

What is expanded polystyrene afraid of?

Expanded polystyrene does not react in any way to substances such as soda, soap and mineral fertilizers. It does not interact with bitumen, cement and gypsum, lime and asphalt emulsions. Groundwater also does not care for him. But turpentine with acetone, some brands of varnishes, as well as drying oil can not only damage, but also completely dissolve this material. Expanded polystyrene dissolves in most products obtained by distillation of oil, as well as in some alcohols.

Just do not like styrofoam (neither foamed nor extruded) direct sunlight. They destroy it - with constant ultraviolet radiation, the material first becomes less elastic, losing strength. After this, the matter of destruction is completed by snow, rain and wind.

Video. Polyfoam and acetone - chemical experience

About the ability to absorb sounds

If you need to escape from excessive noise, expanded polystyrene absolutely will not help. It is somewhat muffled in a state to beat shock, but only on condition that it will be laid in a sufficiently thick layer. But airborne noise whose waves propagate through the air, polystyrene foam is too tough. These are the design features and the properties of expanded polystyrene - rigidly located cells with air inside are completely isolated. So for sound waves flying through the air, it is necessary to put obstacles from other materials.

About biological sustainability

As it turned out, mold on polystyrene foam is not able to live. This is confirmed by American scientists who in 2004 conducted a series of laboratory studies. These works were ordered by polystyrene foam manufacturing companies from the USA. The result completely satisfied them.

The whole truth about harmlessness, incombustibility and a long service life

Polystyrene can serve for many years without losing its properties - tests have shown that it can be thawed and frozen many times, and the quality of the material does not suffer. This material is not subject to burning, as it contains special substances - flame retardants. All this seems absolutely correct and undeniable, but only at first glance. There are several nuances. We will talk about them further.

Environmental issue

Unfortunately, polystyrene is oxidized in air. Moreover, foamed polystyrene foam having a looser structure is more susceptible to this process. Extruded material is oxidized more slowly, but the same fate awaits him. The polystyrene foam that has just been laid also emits styrene, since the complete polymerization of the material is not possible at the production stage. In the meantime, until the polymerization is complete, the release of styrene will not stop.

Manufacturers are trying to challenge information about the harmfulness of expanded polystyrene. They say their products are less harmful than wood. This refers to the emission of harmful substances by a tree during combustion. Indeed, the combustion of expanded polystyrene produces carbon dioxide, carbon monoxide and soot. But if the expanded polystyrene is heated to a temperature exceeding 80 degrees, then the vapor of harmful substances is released. They contain fumes: styrene, toluene, ethylbenzene, benzene and carbon monoxide.

Combustibility issue

In fact, any polystyrene foam burns. Manufacturers are cunning, stating that it dies out on its own, being less dangerous than a tree - alas, this is not so. Such a statement clearly contradicts the Russian GOST 30244-94, according to which foams are classified as G3 and G4 in flammability - the most dangerous.

One way to pervert the facts is to effectively hang a polystyrene foam board in the air, and then set it on fire. To do this, the stove is exposed from below with a lit burner. The result speaks for itself - only the piece that was in contact with the burner burns out, and then the fire does not go on.

But this experience does not correspond to the actual operating conditions, and can only serve as a focus. But if you put a piece of expanded polystyrene on a plane of non-combustible material and set it on fire, it will not go out at all. After all, hot drops of polystyrene foam, formed when a small piece is heated, will transfer fire to its entire surface. The result is not long in coming - the stove will burn completely.

If we take expanded polystyrene, which does not include flame retardants, then its smoke generation coefficient is 1048 square meters per kilogram. In polystyrene foam with a self-extinguishing effect, this figure is greater - 1219 square meters per kilogram. For rubber, for example, it is 850 square meters per kilogram, and for wood even less - only 23 square meters per kilogram. To make it clearer, we give the following figures: if the smoke in the room is more than 500 square meters per kilogram, then, stretching out your hand, you can not see her fingers.

Fire retardants (most often hexabromocyclododexane) are added to expanded polystyrene to increase its fire safety. In our country, it is customary to designate such a polystyrene foam with the letter “C”. This should, in theory, mean that the material has the property to decay on its own. But in practice it turns out that polystyrene foam with a flame retardant burns no worse than it does not contain this additive. It only lights up worse, without doing this spontaneously at elevated temperatures. Its flammability class is G2, but after a few years it turns into G3 or G4 - the flame retardant properties deteriorate over time.

However, it should be noted that polystyrene foam in building structures is never used in open form. On top of this material, facade plaster is always applied or a screed is mounted. Therefore, building structures, which include polystyrene foam, are fireproof.

Life span issue

If you properly operate polystyrene foam, covering it from above with plaster or another protective and decorative layer, then it will last 30 years, no less. True, in reality everything is not so rosy - either the craftsmen blind the insulation quickly somehow, the customer will try to save on materials, the inexperienced master will make mistakes when installing polystyrene boards.

One of such errors is an incorrect calculation of the thickness of the insulation. It seems to many that if you take a thick thirty-centimeter foam plate, it will last longer, and it will be warmer in the house. But this is not so - material of large thickness from temperature extremes will go through cracks and waves, under which cold air will penetrate. It should be noted that in Europe the norm has been adopted - to insulate houses outside with expanded polystyrene no more than 3.5 centimeters. thick. This allows you to reduce the risk of poisoning during a fire.

How to accurately select polystyrene foam

Expanded polystyrene is one of the most popular building materials. It is light, warm and cheap, and working with it is very simple. Since demand is great, there are more and more offers from manufacturers. And each of them assures that it is his expanded polystyrene that is the best, and with quality beyond all praise.

1. Lost in countless offers, do not rush to buy material. First, carefully study its parameters. If you need to insulate the facade, take PSB-S polystyrene foam, positioned as self-extinguishing. His mark should be no lower than the fortieth. And if the brand has the number 25 or less, then do not look in the direction of such material - it is only suitable for packaging, but not for construction work.

2. When buying material, check to what standards it is made.If the manufacturer does not produce products according to GOST, but according to their own specifications, then the characteristics of the material may vary. For example, PBS-S-40 polystyrene foam (fortieth grade) can have a different density - from 28 to 40 kilograms per cubic meter. It is advantageous for the manufacturer to mislead the buyer in this way - less money is spent on the production of expanded polystyrene. Therefore, you can not focus only on the number in the brand name, but you must ask to show documents confirming the technical characteristics of expanded polystyrene.

3. Before buying, try to break off a piece of material from the edge. If it turns out to be a low-grade packaging foam, then it will break with an uneven edge, on the sides of which round small balls will be visible. The material obtained by extrusion, at the place of a neat fracture, has regular polyhedrons. The fault line will run through some of them.

4. As for manufacturers of expanded polystyrene, the best of them are the European companies Polimeri Europa, Nova Chemicals, Styrochem, BASF. Not far behind them are Russian manufacturing companies, such as, for example, Penoplex andTechnoNIKOL". They have a production capacity that is enough for the manufacture of expanded polystyrene of very high quality.

Conclusion

Although polystyrene foam, as it turned out, is a combustible material and emits harmful substances when heated strongly, it remains one of the most popular heat insulators. Indeed, as a heater, polystyrene foam has a lot of advantages: it is the cheapest, easy to cut with an ordinary knife, almost does not absorb moisture and holds heat well. It is not for nothing that four out of five European buildings have polystyrene foam insulation of the facade. Moreover, both residential buildings and offices, and industrial premises.

True, it is too early to talk about lengthy studies of this material - even half a century has not passed since the beginning of its use. Therefore, those who talk about the service life of expanded polystyrene for more than 80 years can confirm their words only by tests in the laboratory. But they shouldn’t be completely trusted - because in order to get the desired results, you can send special samples to the laboratory.

The most important thing when using expanded polystyrene in the environment is to reliably protect it from sunlight and atmospheric influences. To do this, use a plaster mixture, which includes cement. The coating should be applied tightly, there should not be a single gap. Otherwise, a tiny ray of sunlight can completely destroy thermal insulation over time.

But inside polystyrene foam for insulation should not be used, no matter what the manufacturers say. Let them tell themselves, but in the event of a fire they will not be near, but the combustion products can cause great harm, taking away the health, and sometimes even people's lives. An example is the well-known tragedy in the club Lame Horse, where most visitors simply suffocated by the combustion products of this heater.